How to Fabricate Pouch Cells ? (Lab Line)

Posted by Chia-yu Chen on

Pouch cell fabrication involves several steps:

Slurry preparation --> Slurry coating --> Calendaring --> Cut electrode --> Electrode stacking --> Weld current collectors and then tab together --> Produce a pouch case --> Top & side sealing --> Electrolyte filling --> Primary sealing (vacuum standing and vacuum seal) --> Battery formation (Charge/discharge) --> Degassing à Secondary sealing.

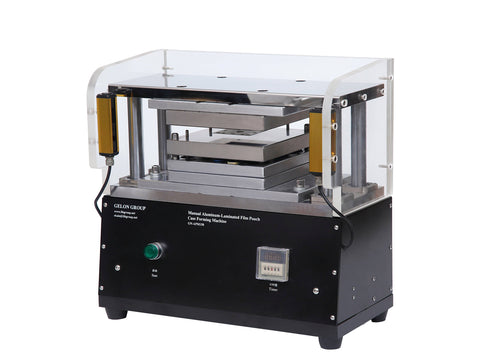

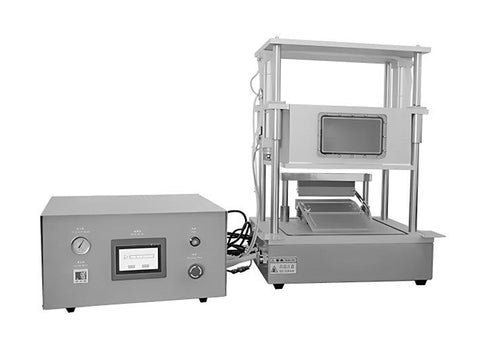

MSE PRO battery fabrication equipment includes a wide range of production machines from slurry making to final sealing system.

The flow chart below is the typical process for equipment that will be used for a R & D lab.

Pouch Cell Fabrication Process Flow

MSE Supplies offers various equipment and tools for pouch cell fabrication. MSE Supplies also offers customized products. If you need any customization such as different size of pouch cells, please contact us at sales@msesupplies.com.

Share this post

- Tags: Brands - MSE PRO, Industry - Lithium Battery & Renewable Energy, Products - Lithium Battery Materials & Tools