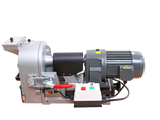

MSE PRO Laboratory Disc Mill

SKU: MA1125

To better serve you, we would like to discuss your specific requirement.

Please Contact Us for a quote.

MSE Supplies offers laboratory disc mill, which is firm and durable, applicable to pre-grinding and fine grinding for medium hard, hard and brittle solid materials. It can grind samples into 100μm particles very quickly.

Contact us today to discuss your needs.

Working Principle

The samples are grinded via the pressure and frictional force generated between a rotating disc and another fixed disc. After the sample enters into grinding chamber, the progressively arranged teeth of the grinding disc first subject the sample to preliminary crushing, centrifugal force then moves it to the outer regions of the grinding discs where fine grinding takes place. The ground sample falls into the sample receiver via the gap of the grinding discs.

Features and advantages

- Simple operation, easy cleaning.

- The sample feed size up to 20mm.

- Large processing capacity of samples.

-

The gap of grinding discs can be adjusted continuously.

-

Efficient sample treatment, extreme size reduction can be reached in a short time.

-

Grinding discs made of various materials are available for selection and wear-resistant.

- Dust discharge connector design can prevent sample powders from polluting environment.

Applications of Laboratory Disc Mill:

Technical Data

| Feed size | <20mm |

| Final fineness | <75μm |

| Speed | 470rpm |

| Collector capacity | 2.5L |

| Digital precision | 0.01mm |

| Rated power | 1.5kW |

| Power supply | 380V, 50Hz |

| Instrument size (W*D*H) | 410*880*440mm |

| Package size (W*D*H) | 600*1160*625mm |

| Weight | 136kg |